By Julie Range

Policy Manager, Commission Shift

Produced water is a huge issue for oil and gas operations. For every barrel of oil produced, between four to nine barrels of dirty water full of salty, dissolved solids also flow to the surface. Historically, it’s been cheaper to inject this dirty water back underground. However, disposing of produced water underground pressurizes aquifers. This buildup of pressure is causing earthquakes and inactive wells to return to life as zombie wells that leak produced water or, more rarely, as geysers.

Wouldn’t it be great if some of this oversupply of dirty water was diverted and cleaned enough to supply the demand for water in the parched corners of the Permian Basin? The challenge is how to do this at a reasonable cost. Separating solids and liquids in produced water requires equipment and energy.

Many companies, including Texas Pacific Water Resources, are looking at how to clean up this water for beneficial reuse. Directly reusing this water without cleaning it risks ruining the soil by allowing salts or other potentially unsafe components, like benzene or naturally occurring radioactive materials, that come up in produced water to bioaccumulate in our food sources.

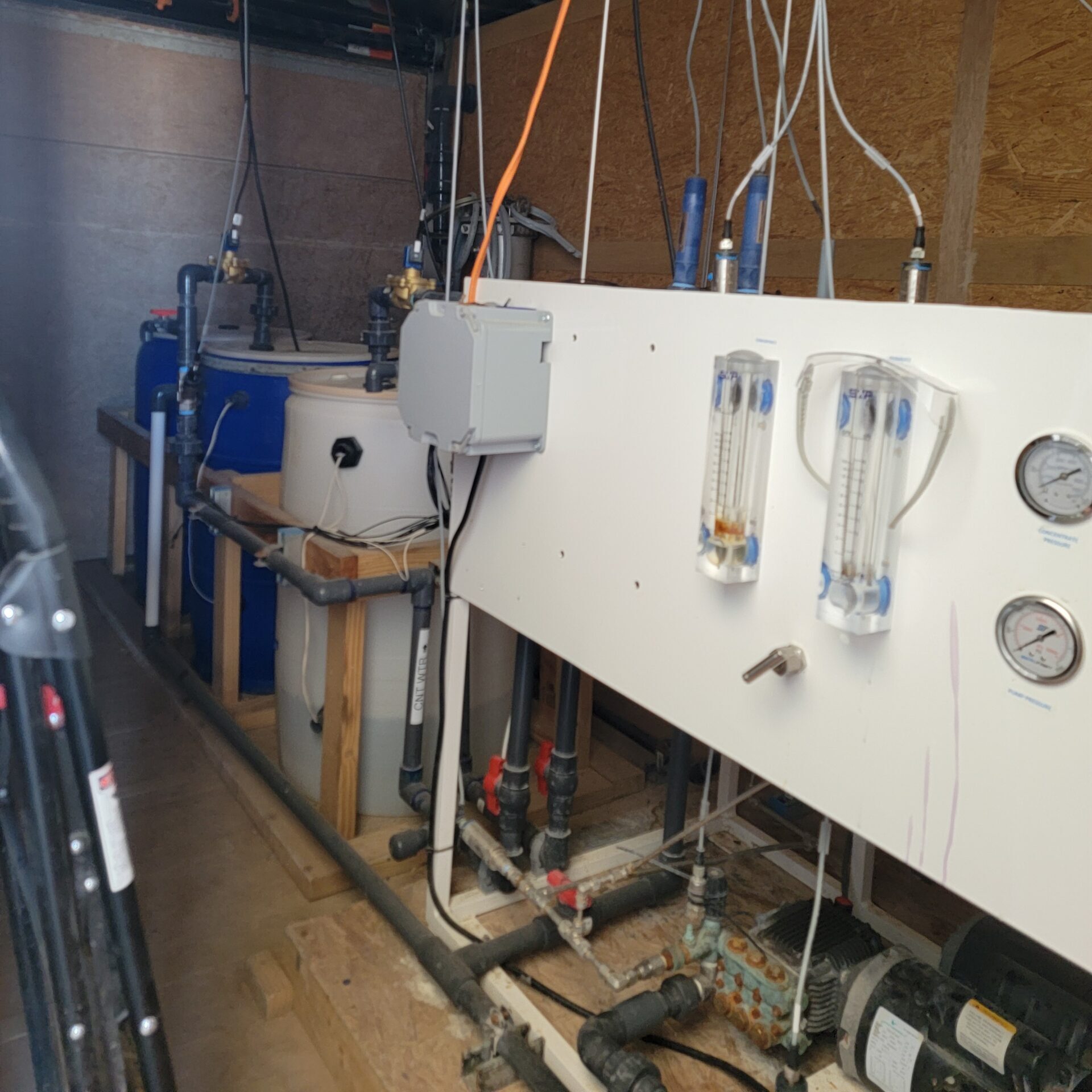

Adrianne Lopez Billings, the research and development manager at Texas Pacific Water Resources, kindly gave me a tour earlier this month of the Texas Pacific Water Resources pilot facilities, where they are working to develop and test technologies to clean that produced water for beneficial reuse.

To ensure the water is fully clean, it goes through multiple steps to filter and separate all potentially harmful materials. If done right, the cleaning process is so intense that not only is the bad stuff removed, but so is the good stuff — like common minerals in groundwater that some plants need. According to Adrianne, it’s better to be safe and ensure all questionable components have been removed, and then add back the deficient good minerals plants need to grow healthy if that step is required.

Being one of the first projects of its kind, Texas Pacific Water Resources is taking additional steps to prove the process is safe for native plants and grasses as well as common agricultural crops like alfalfa. They set up a greenhouse and a test plot outdoors and collected soil, plant, and water samples. While they wait for final test results, preliminary data from over 400 different contaminant tests are very promising and appear to demonstrate their ability to produce clean water. They plan to publish their findings and have shared the preliminary results with the Railroad Commission and the Texas Commission on Environmental Quality.

Touring the plant and seeing the effort Texas Pacific Water Resources has put into validating its process and outputs offers the hope that produced water can be cleaned for beneficial reuse. The challenge will come with ensuring we have rules and oversight in place that ensure all water clean-up facility outputs are consistently safe and protective of human and environmental health. Most people working on this problem, like Adrianne, are working to achieve these results.

Julie Range and Adrianne Lopez Billings on the facility tour.

Adrianne Lopez Billings describes one of the steps in the separation process.

Additional photos of tanks in the separation process.

Photos of the greenhouse, minus plants that were harvested and sent for testing.

Photos of the alfalfa plot to compare water irrigated with cleaned produced water and that from water irrigated from a well.